Reti in poliuretano

Reti in poliuretano

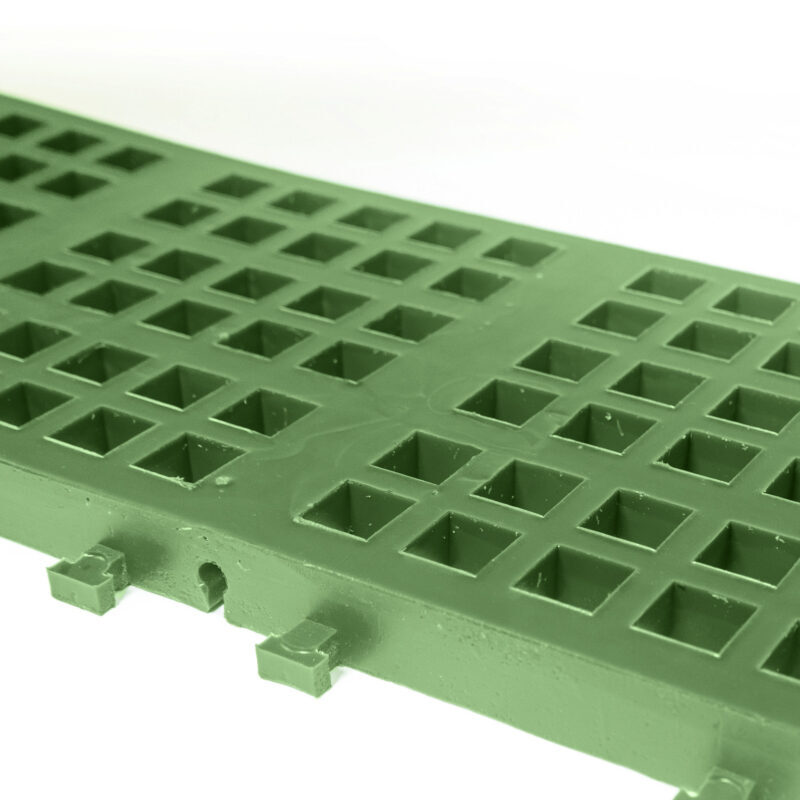

I piani vaglianti in poliuretano si caratterizzano per le seguenti proprietà:

• alta resistenza all’usura, fino a 12 volte quella delle equivalenti reti in acciaio

• assenza di corrosione

• forte riduzione del rumore

• buon effetto anti-intasamento, grazie alla conicità dei fori ed alla flessibilità del materiale

• disponibilità di differenti qualità e durezze di poliuretano

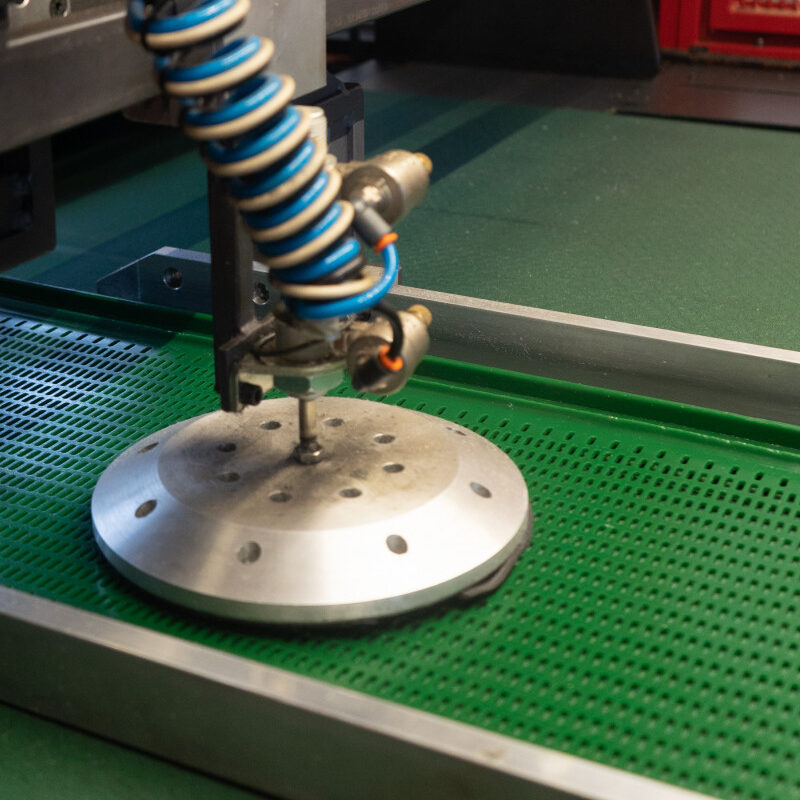

Nel suo stabilimento Sovatec produce reti in poliuretano di tutte le tipologie.

In particolare:

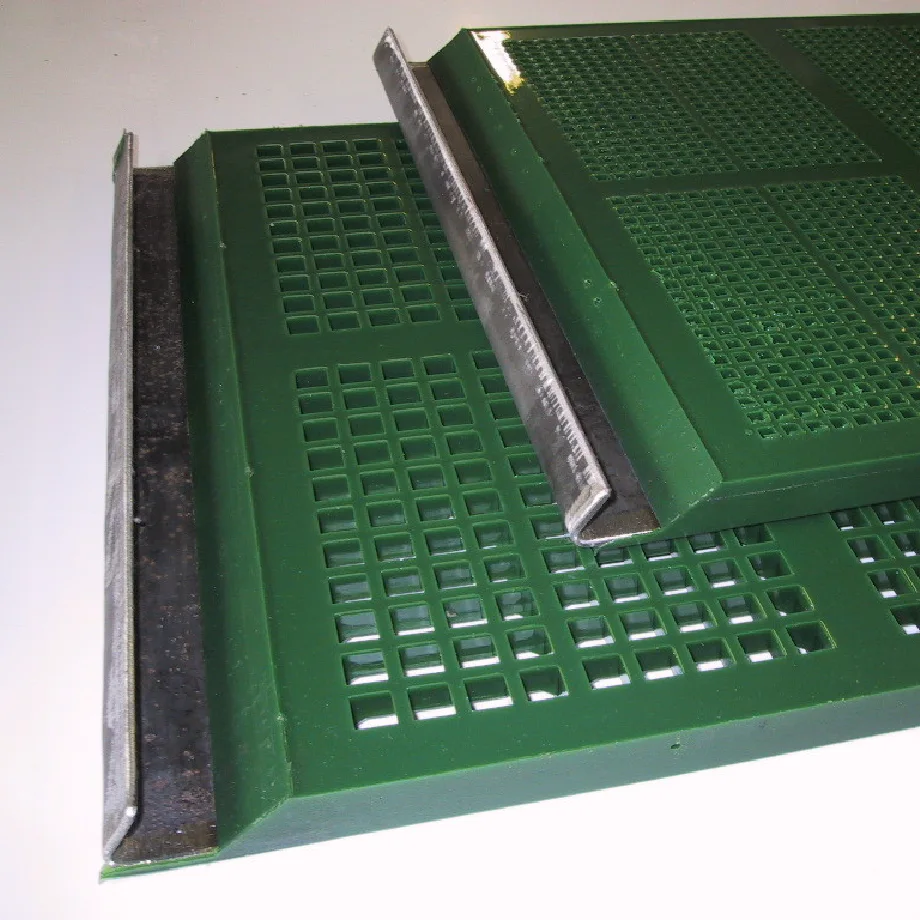

• reti con ganci di tensionamento laterali

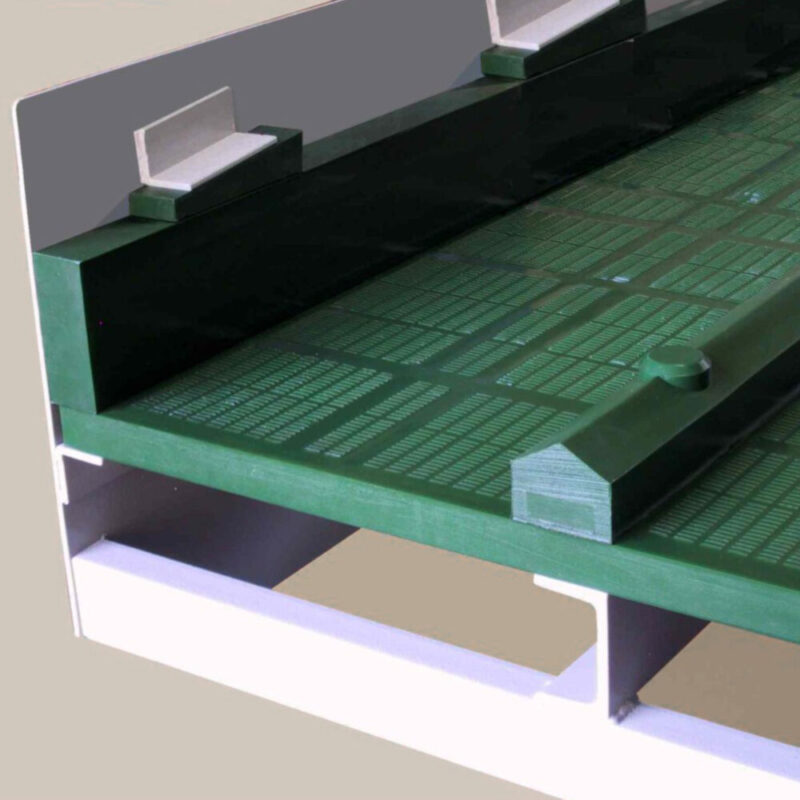

• reti autoportanti

• pannelli modulari

• reti tipo flip-flow

• pannelli per vagli asciugatori

Il magazzino stampi di Sovatec, formatosi nel corso di oltre 25 anni di attività, consente di far fronte alle più diverse richieste sia per quanto riguarda le tipologie e le dimensioni delle reti sia per quanto riguarda la dimensione dei fori.

Principali fori disponibili

| Fori quadri (mm) |

Spessore rete (mm) |

Spessore totale (mm) |

|---|---|---|

| 1,4×1,4 | 5 | 30 |

| 1,9×1,9 | 5 | 30 |

| 2,3×2,3 | 5 | 30 |

| 3×3 | 5 | 25 / 30 |

| 3,5×3,5 | 5 | 25 / 30 |

| 4×4 | 6 | 25 / 30 |

| 4,5×4,5 | 6 | 25 / 30 |

| 5×5 | 7 | 25 / 30 |

| 5,5×5,5 | 7 | 25 / 30 |

| 6×6 | 8 | 25 / 30 |

| 6,5×6,5 | 8 | 25 / 30 |

| 7×7 | 9 | 25 / 30 |

| 8×8 | 10 | 25 / 30 |

| 9×9 | 10 | 25 / 30 |

| 9,5×9,5 | 10 | 25 / 30 |

| 10×10 | 10 | 25 / 30 |

| 10,5×10,5 | 10 | 25 / 30 |

| 11×11 | 10 | 25 / 30 |

| 11,5×11,5 | 10 | 25 / 30 |

| 12×12 | 12 | 25 / 30 |

| 13×13 | 13 | 25 / 30 |

| 13,5×13,5 | 13 | 25 / 30 |

| 14×14 | 13 | 25 / 30 |

| 15×15 | 13 | 25 / 30 |

| 16×16 | 15 | 25 / 30 |

| 17×17 | 15 | 25 / 30 |

| 18×18 | 18 | 25 / 30 / 35 |

| 19×19 | 18 | 25 / 30 / 35 |

| 20×20 | 18 | 25 / 30 / 35 |

| 20,5×20,5 | 18 | 25 / 30 / 35 |

| 21×21 | 18 | 25 / 30 / 35 |

| 22,5×22,5 | 18 | 25 / 30 / 35 |

| 24×24 | 22 | 30 / 35 / 40 |

| 24,5×24,5 | 22 | 30 / 35 / 40 |

| 25×25 | 22 | 30 / 35 / 40 |

| 27×27 | 22 | 30 / 35 / 40 |

| 28×28 | 22 | 30 / 35 / 40 |

| 30×30 | 25 | 30 / 35 / 40 |

| 32,5×32,5 | 25 | 35 / 40 |

| 34×34 | 25 | 30 / 35 / 40 |

| 35×35 | 25 | 30 / 35 / 40 |

| 36×36 | 25 | 30 / 35 / 40 |

| 38×38 | 25 | 35 / 40 |

| 40×40 | 25 | 35 / 40 |

| 42×42 | 25 | 30 / 35 / 40 |

| 45×45 | 30 | 35 / 40 |

| 47×47 | 30 | 35 / 40 |

| 50×50 | 30 | 35 / 40 |

| 53×53 | 30 | 35 / 40 |

| 55×55 | 30 | 35 / 40 |

| 57×57 | 30 | 35 / 40 |

| 60×60 | 30 | 35 / 40 |

| 63×63 | 35 | 40 / 45 / 50 |

| 70×70 | 35 | 40 / 45 / 50 |

| 75×75 | 35 | 40 / 45 / 50 |

| 80×80 | 40 | 45 / 50 |

| 83×83 | 60 | 70 / 80 |

| 85×85 | 35 | 40 / 45 / 50 |

| 90×90 | 40 | 45 / 50 |

| 100×100 | 40 | 45 / 50 |

| 110×110 | 40 | 45 / 50 |

| 120×120 | 40 | 45 / 50 |

| 130×130 | 40 | 45 / 50 |

| Fori asola e rettangolari (mm) |

Spessore rete (mm) |

Spessore totale (mm) |

|---|---|---|

| 0,3×11 | 10 | 30 / 35 / 40 |

| 0,4×11 | 10 | 30 / 35 / 40 |

| 0,6×11 | 10 | 30 / 35 / 40 |

| 0,75×11 | 10 | 30 / 35 / 40 |

| 1×11 | 10 | 30 / 35 / 40 |

| 1×18 | 10 | 30 / 35 / 40 |

| 1,5×11 | 10 | 30 / 35 / 40 |

| 2×17 | 10 | 25 / 30 |

| 2,5×17 | 10 | 25 / 30 |

| 3×17 | 10 | 25 / 30 |

| 3,5×17 | 10 | 25 / 30 |

| 4×20 | 10 | 25 / 30 |

| 4,5×24 | 10 | 25 / 30 |

| 5×26 | 10 | 25 / 30 |

| 6×26 | 10 | 25 / 30 |

| 7×26 | 10 | 25 / 30 |

| 10×20 | 18 | 30 / 35 |

| 15×45 | 13 | 30 / 35 |

| 19,5×40 | 22 | 35 |

| 28×72 | 25 | 35 / 40 |

| Fori quadri (mm) |

Spessore rete (mm) |

Spessore totale (mm) |

|---|---|---|

| 8 | 9 | 25 / 30 |

| 10 | 10 | 25 / 30 |

| 12 | 12 | 25 / 30 |

| 15 | 15 | 25 / 30 |

| 17 | 15 | 25 / 30 |

| 25 | 20 | 30 / 35 |

| 28 | 24 | 35 / 40 |

| 30 | 24 | 35 / 40 |

| 32,5 | 24 | 35 / 40 |

| 35 | 24 | 35 / 40 |

| 40 | 30 | 35 / 40 |

| 50 | 35 | 40 / 45 |

| 65 | 30 | 35 / 40 |

| 80 | 35 | 40 / 45 |

| 90 | 35 | 40 / 45 |

| 120 | 35 | 40 / 45 |

Richiesta informazioni

Invia un messaggio per richiedere informazioni sui nostri prodotti e servizi!

Compila il form per essere ricontattato